"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

04/07/2017 at 18:00 ē Filed to: 41TE, Automatic Transmission, Rebuild, Blog

3

3

10

10

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

04/07/2017 at 18:00 ē Filed to: 41TE, Automatic Transmission, Rebuild, Blog |  3 3

|  10 10 |

Because this is a FWD transaxle, we have the additional task of putting together a transfer geartrain and differential.

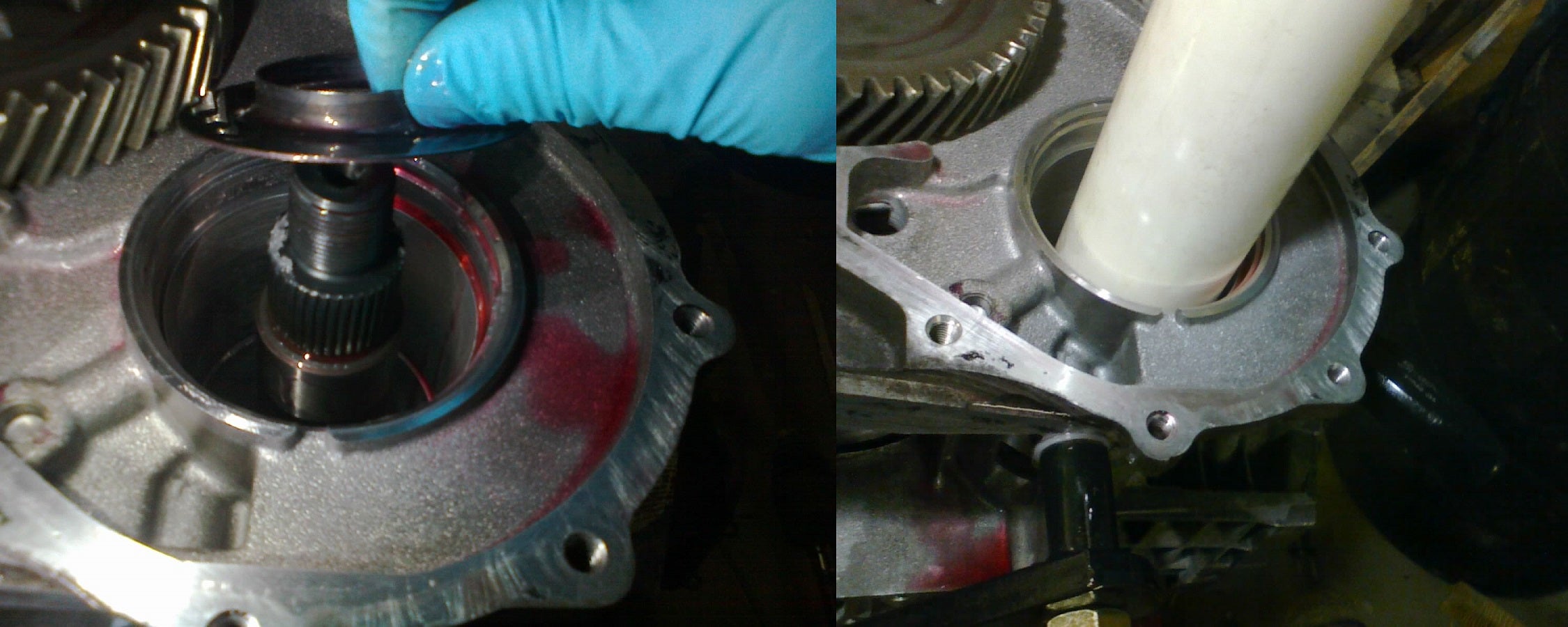

A fresh O-ring goes on the transfer shaftís ďlowerĒ bearing race

LEFT: The shaft & its lower bearing go into the case, and are topped with this baffle. RIGHT: A length of PVC pipe can be used to hammer the baffle & race down into position.

Those special pliers make another appearance to help put the snap-ring back in, which retains the lower end of the transfer shaft

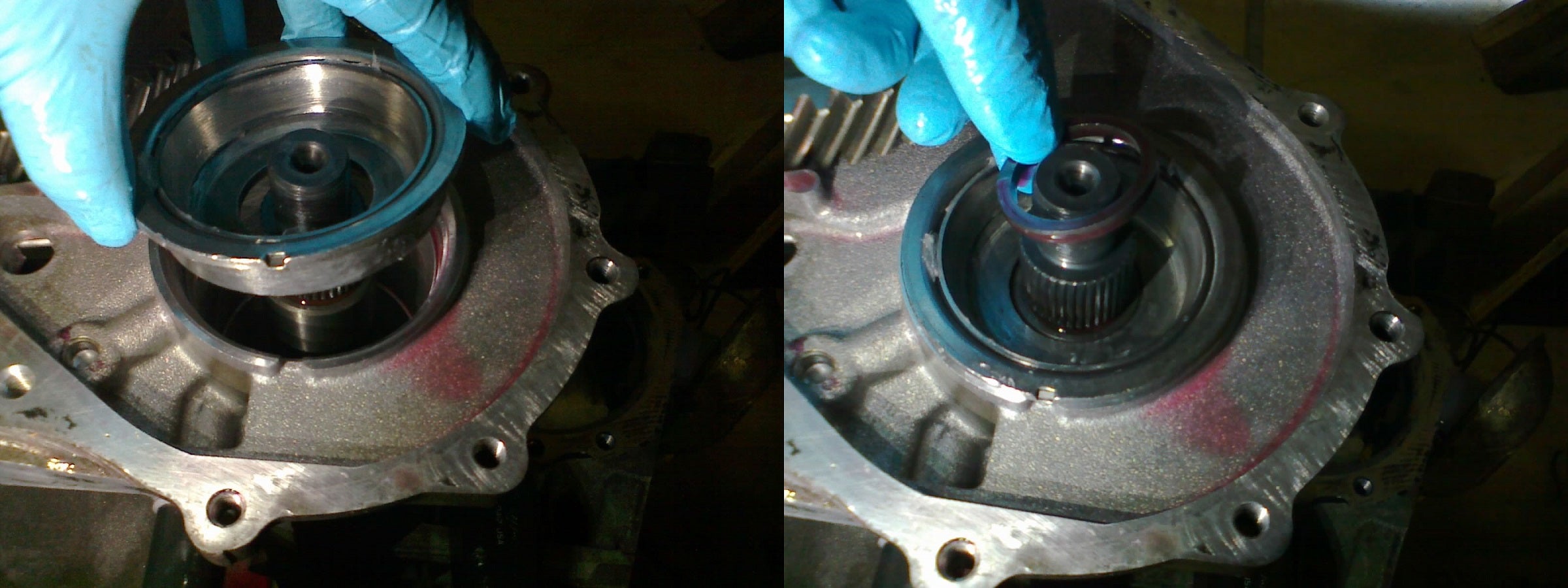

The upper race retainer & race drop in, and this shim slides on

Now we can slide the transfer gear onto the shaft

Then we tighten the retaining nut with the washer to pull the transfer gear down onto the shaft. This seats the bearings against their respective races and lines up the transfer (driven) gear to the output (drive) gear.

The extension housing and the other bearing retainer get new seals pressed in

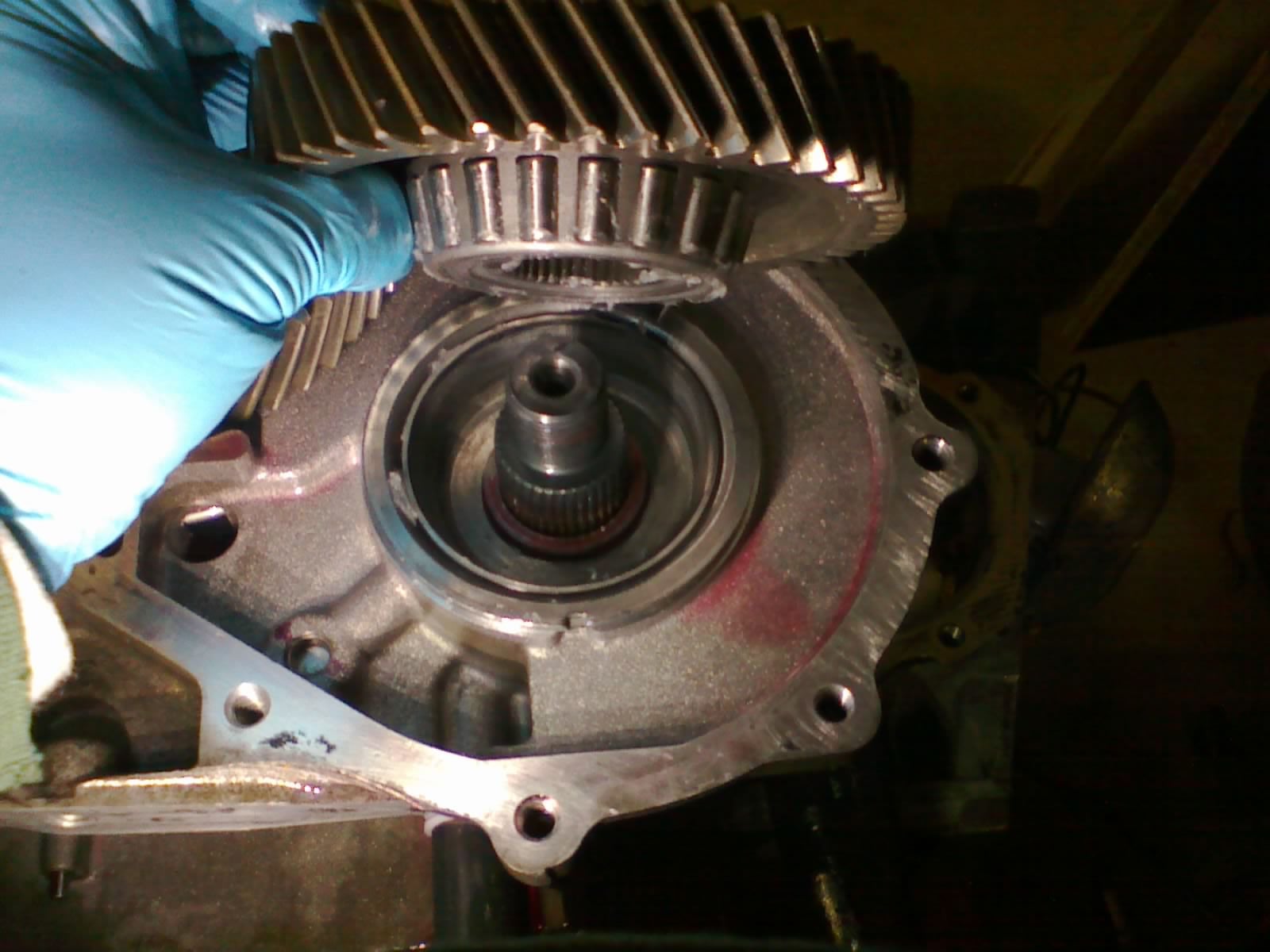

Both of these retainers go in at the same time, with the heavy differential carrier assembly in between them. (If I had an extra arm, Iíd have pictures for you.) Alas...

The ring gear is meshed with the transfer gear, and the carrier floats between the diff retainers. The rebuild kit did not come with a gaskets for the covers, and the instructions call for RTV anyway.

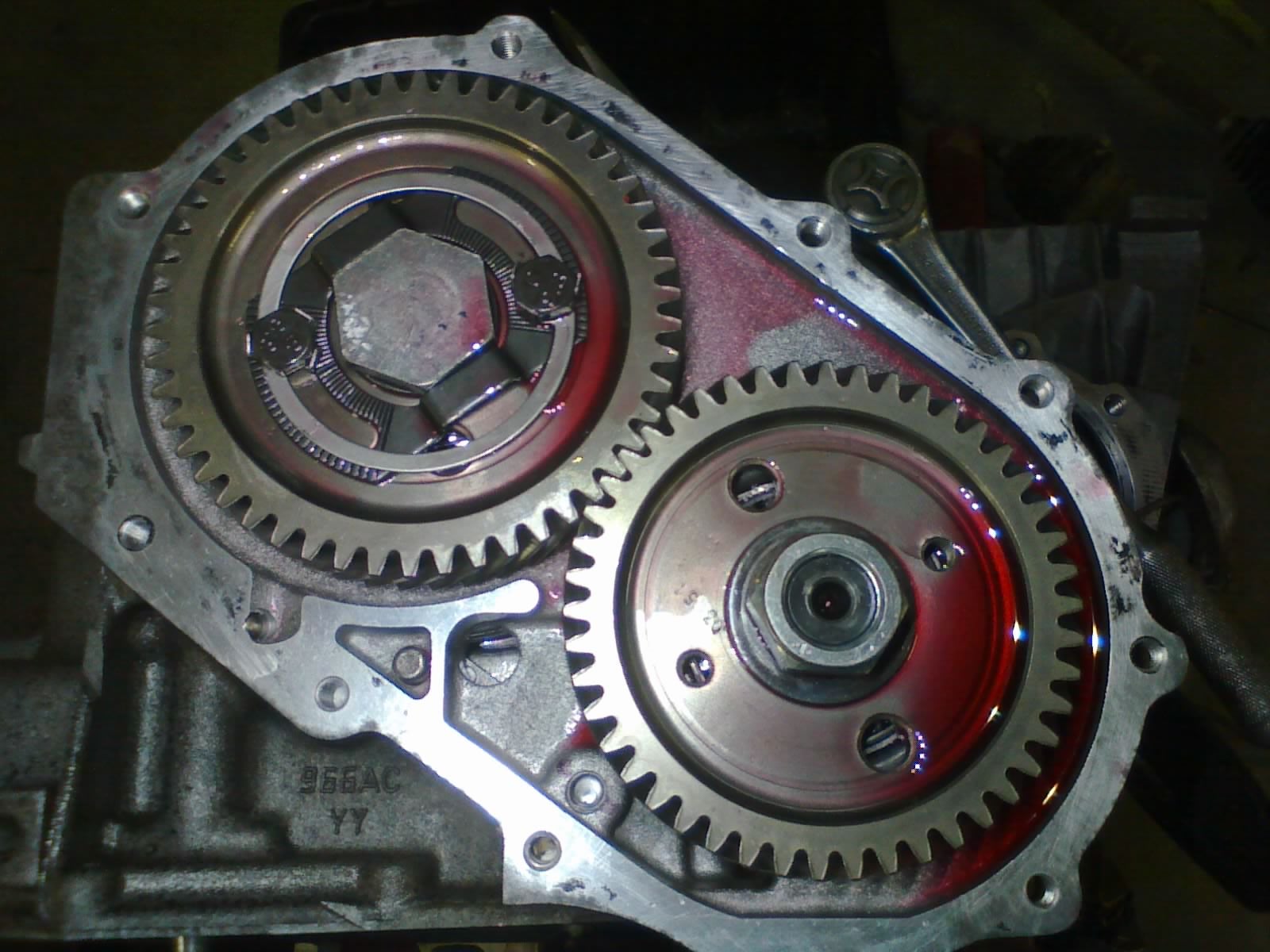

Diff cover and transfer gear cover cleaned up, RTVíd and torqued to spec

Now we can slide the head off of the engine stand (careful, the transmission is heavy!), set it down, and unbolt the head of the stand from the bottom of the case. With the tranny separated from the stand, we now have access to re-install the valve body. But we have to put that valve body back together first... !!!error: Indecipherable SUB-paragraph formatting!!!

TahoeSTi

> Urambo Tauro

TahoeSTi

> Urambo Tauro

04/07/2017 at 18:08 |

|

You are making me think I really can rebuild my 8.8 myself....itís so much simpler than this....Wow!

Urambo Tauro

> TahoeSTi

Urambo Tauro

> TahoeSTi

04/07/2017 at 18:13 |

|

Well, now you got me wishing that I had taken pictures of my 8.8 rebuild...

TahoeSTi

> Urambo Tauro

TahoeSTi

> Urambo Tauro

04/07/2017 at 18:17 |

|

Now you have me wishing you did.....I have 2 to do, One is getting a Detroit Ture Track and 31 spline axels, is just going to get a basic rebuild.....I also have a few t-5.....Maybe I can get a some good pics when I do it....This weekend itís a new CV Shaft for the outback.

Urambo Tauro

> TahoeSTi

Urambo Tauro

> TahoeSTi

04/07/2017 at 18:24 |

|

I havenít gotten into a T-5 yet, but Iím sure I will someday.

As for my 8.8, I guess I got lucky. I was able to re-use the original shims, as the new bearings brought everything back into spec. The worst part was that the axle was in-car, and I was laying on the garage floor while wrenching on it.

TahoeSTi

> Urambo Tauro

TahoeSTi

> Urambo Tauro

04/07/2017 at 18:27 |

|

The 8.8 thatís out of the car just needs new bearings. The one in the car now is getting new everything..... so i guess i need to figure out how to get the shims right....If you want a t-5 to break into I have 3 out of the car broken and one in the car working.

Urambo Tauro

> TahoeSTi

Urambo Tauro

> TahoeSTi

04/07/2017 at 18:51 |

|

Yeah, with new gears & Truetrack (nice choice BTW), I kinda doubt that youíll get to use the old shims. What you might want to do is, try to save the old bearings so that you can use them for test-fitting.

MM54

> Urambo Tauro

MM54

> Urambo Tauro

04/07/2017 at 22:25 |

|

Blue RTV on the differential cover?

Urambo Tauro

> MM54

Urambo Tauro

> MM54

04/07/2017 at 22:29 |

|

Kinda stands out, doesnít it? The old sealant that I scraped off was black. FWIW, the blue stuff is what was shown in the ATRA rebuild guide.

MM54

> Urambo Tauro

MM54

> Urambo Tauro

04/07/2017 at 22:41 |

|

Interesting. Iíve always used black or grey for oil-containing things since itís specially made to be very oil-resistant

Urambo Tauro

> MM54

Urambo Tauro

> MM54

04/07/2017 at 22:45 |

|

Same here. I double-checked the specs on Ultra Blue, and itís got the necessary temperature range, and claims to be sufficiently oil-resistant, too. Ultra Black is supposedly for ďmaximumĒ oil resistance, but when I saw Blue used in the guide, I figured that I was probably overthinking it.